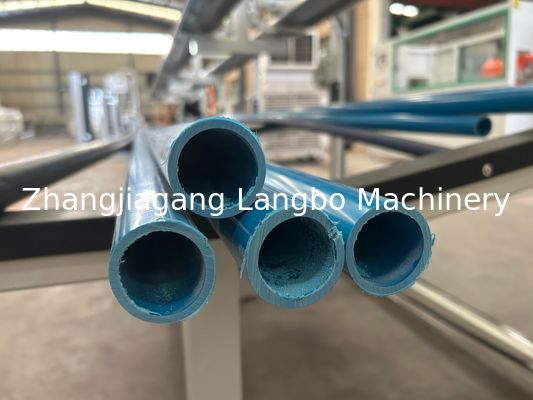

Plastic Water Drainage PVC UPVC Pipe Tube Making Machine Extrusion Production Line

Short desciption

We provide a range of plastic pipe production lines, including 16-630mm PVC/UPVC pipe lines, 16-1200mm HDPE pipe lines, as well as lines for PP/PPR pipes, HDPE/PP/PVC double-wall corrugated pipes, and single-wall corrugated pipes. These lines can produce pipes for various applications such as water supply, drainage, gas supply, and conduit wiring. Specifically, the PVC pipe production line manufactures PVC pipes of different diameters and wall thicknesses, widely used in agricultural water supply, drainage, and electrical conduits.

Application

The UPVC pipes produced find extensive use in both industrial and daily scenarios, including electrical conduits, water supply pipes, sewage pipes, home decoration, chemical transportation, and gas distribution lines. They boast high strength and rigidity, structural integrity, excellent chemical resistance, durability, thermal stability, non-toxic safety, low maintenance needs, and cost-effectiveness.

Producting process

PVC powder + additives → Mixing → Spring feeding → Twin-screw extruder → Mould and calibrator → Vacuum forming machine → Haul-off machine → Cutting machine → Stacker.

Specifications:

| MODEL |

PIPE DIAMETER (MM) |

EXTRUDER MODEL |

MOTOR POWER (KW) |

| LB-32F |

16-32 (FOUR PIPE) |

SJSZ65/132 |

37 AC |

| LB-32E |

16-32 (DOUBLE PIPE) |

SJSZ51/105 |

22 AC |

| LB-32W |

16-32 (DOUBLE PIPE) |

SJSZ65/132 |

37 AC |

| LB-40E |

16-40 (DOUBLE PIPE) |

SJSZ51/105 |

22 AC |

| LB-40W |

16-40 (DOUBLE PIPE) |

SJSZ65/132 |

37 AC |

| LB-50E |

16-50 (DOUBLE PIPE) |

SJSZ51/105 |

22 AC |

| LB-50W |

16-50 (DOUBLE PIPE) |

SJSZ65/132 |

37 AC |

| LB-63W |

16-63 (DOUBLE PIPE) |

SJSZ65/132 |

37 AC |

Product detail

Mixer

Boasting a specialized design, the mixer reduces raw material self-friction, which enhances energy utilization efficiency. Equipped with a vacuum suction loading system, it operates with low noise and maintains a dust-free working environment.

Twin screw extruder machine

Crafted with top-brand components, the extruder ensures stable production, high efficiency, and long-term durability. Its conical twin-screw design is tailored to raw material characteristics, enabling homogeneous mixing, superior plastification, and efficient conveying.

Vacuum Calibration & Cooling

The vacuum calibration tank features a two-chamber structure, integrating vacuum calibration and cooling functions. Both the vacuum tank and spraying cooling tank are made of 304 stainless steel. The high-performance vacuum system guarantees precise pipe sizing.

Haul-off Unit

Equipped with three caterpillar belts, the haul-off machine ensures stable movement of produced pipes. By adjusting the general control, it can be customized into tailored hauling modes to meet specific production requirements.

Cutting Unit

A high-precision encoder ensures accurate and stable cutting lengths. Controlled by a PLC system, it supports manual operation for cutting according to specific application needs.

Technical Features:

1- PLC control, high degree of automation

2- Adopting special screw and barrel, good effect

3- Adopting compound spiral engine head, effectively eliminate memory function of the material

4- Easy operate and need less worker

5- Convenient for maintaining

Delivery information:

1. Delivery: 30 days after ur order

2. Warrenty: 12 months

3. Payment: T/T 30% in advance, T/T 70% before delivery.

4. Packing: Standard export wooden case

Our Service

1. One year guarantee for whole machine.

2. 24 hours technical support.

3. Our engineers can provide installation & commission service overseas.

4. After a year, we can instruct you how to maintain the machine, and spare parts are provided with the best price.

5. We also can provide training service which help operators handle the machine well.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!

Calificación General

Instantánea de calificación

La siguiente es la distribución de todas las calificacionesTodas las reseñas